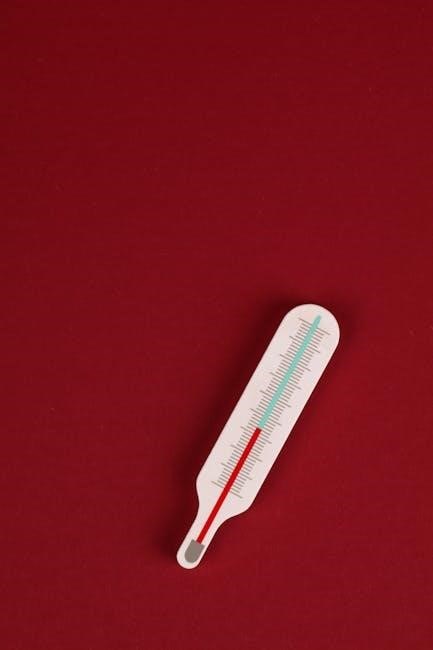

safety first thermometer instructions celsius to fahrenheit

Safety First Thermometers ensure accurate temperature measurement, crucial for workplace safety and health. They provide reliable readings in Celsius or Fahrenheit, aiding in hazard prevention and control, and are essential for maintaining safe working conditions across various industries.

1.1 Overview of Safety First Thermometers

Safety First Thermometers are designed to provide accurate and reliable temperature measurements, ensuring safety and efficiency in various settings. They are built with durability and ease of use in mind, featuring clear displays and intuitive controls. These thermometers are essential for industries requiring precise temperature monitoring, such as healthcare, food safety, and industrial applications. Many models offer dual-scale functionality, allowing users to switch between Celsius and Fahrenheit effortlessly. Their design prioritizes safety, with features like shatter-resistant materials and secure grips to prevent accidents. Regular calibration and maintenance ensure long-term accuracy, making them a trusted tool for professionals. By adhering to safety standards, Safety First Thermometers play a crucial role in preventing workplace hazards and ensuring compliance with regulatory requirements.

1.2 Importance of Temperature Measurement in Safety

Temperature measurement is critical for ensuring safety in various environments. Accurate readings help prevent hazards, such as overheating equipment or improper storage conditions, which can lead to accidents or contamination. In workplaces, precise temperature control is essential for maintaining safe working conditions, especially in industries like manufacturing, healthcare, and food processing. Safety First Thermometers play a vital role in monitoring these conditions, providing reliable data to prevent potential risks. By ensuring compliance with safety standards, these tools help protect workers, equipment, and the environment from temperature-related dangers. Regular use of thermometers fosters a culture of safety, enabling proactive measures to avoid incidents and maintain operational efficiency.

Understanding Temperature Scales

Temperature scales, like Celsius and Fahrenheit, are essential for measuring heat and cold, ensuring safety and comfort in various environments and industrial applications.

2.1 What is the Celsius Scale?

The Celsius scale is a widely used temperature scale developed by Anders Celsius in 1742. It is based on the freezing and boiling points of water, where 0°C represents the freezing point and 100°C the boiling point at standard atmospheric pressure. This scale is particularly popular in scientific and international contexts due to its logical and consistent intervals. Each degree Celsius is equivalent to a 1.8-degree change in Fahrenheit, making it a precise tool for measuring temperature in various applications. The Celsius scale is essential for accurate temperature measurement in fields like meteorology, chemistry, and engineering, ensuring safety and efficiency in operations. Its simplicity and clarity make it a preferred choice for global communication and scientific research.

2.2 What is the Fahrenheit Scale?

The Fahrenheit scale is a temperature scale developed by Gabriel Fahrenheit in 1724. It sets the freezing point of water at 32°F and the boiling point at 212°F, with the interval between these points divided into 180 degrees. Each degree Fahrenheit represents a smaller temperature change compared to Celsius, making it more sensitive for everyday applications. Widely used in the United States, the Fahrenheit scale is common in weather forecasting and general temperature measurement. While it is less prevalent in scientific contexts, where Celsius is preferred, Fahrenheit remains significant in practical uses. The scale is part of the broader system of temperature measurement, which also includes Kelvin, ensuring accurate and reliable readings across various industries and applications.

2.3 History and Development of Temperature Scales

The development of temperature scales dates back to early scientific efforts to measure heat and cold. The Celsius and Fahrenheit scales were introduced in the 18th century by Anders Celsius and Gabriel Fahrenheit, respectively. Celsius proposed a scale based on the freezing and boiling points of water, setting them at 0°C and 100°C. Fahrenheit, however, used a different reference point, setting the freezing point of water at 32°F and boiling at 212°F. Over time, the Celsius scale became the standard for scientific and international use, while Fahrenheit remained prevalent in everyday applications, particularly in the United States. The evolution of these scales reflects the growing understanding of thermodynamics and the need for precise measurement in various fields, including safety and health, where accurate temperature readings are critical.

Converting Celsius to Fahrenheit

Converting Celsius to Fahrenheit is essential for safety and accuracy. Use the formula: °F = (°C × 9/5) + 32. A Safety First Thermometer simplifies this process.

3.1 The Formula for Conversion

The formula to convert Celsius to Fahrenheit is °F = (°C × 9/5) + 32. This mathematical equation ensures accurate temperature conversion, crucial for safety and precision in various applications. Understanding this formula is essential for interpreting readings from Safety First Thermometers, which often provide measurements in both scales. By applying this formula, users can easily switch between Celsius and Fahrenheit, ensuring consistency in temperature monitoring. This conversion method is widely used in industrial, medical, and environmental settings to maintain safety standards and prevent hazards. The formula’s simplicity allows for quick calculations, making it a reliable tool for professionals relying on precise temperature data. Safety First Thermometers are designed to simplify this process, ensuring efficient and accurate conversions for all users.

3.2 Step-by-Step Guide to Manual Conversion

To manually convert Celsius to Fahrenheit, follow these steps:

- Start with the Celsius temperature reading from your Safety First Thermometer.

- Multiply the Celsius value by 9/5 to adjust the scale.

- Add 32 to the result to account for the zero-point difference between the scales.

- Record the final value, which will be the temperature in Fahrenheit.

This method ensures precise conversion, essential for maintaining safety and accuracy in various applications. Always double-check calculations to avoid errors. By following these steps, users can reliably convert temperatures using Safety First Thermometers, ensuring compliance with safety standards and protocols. This process is straightforward and efficient, making it ideal for professionals who need quick and accurate conversions. Proper conversion is critical for interpreting temperature data correctly, especially in environments where precise measurements are vital for safety and health.

3.3 Using a Safety First Thermometer for Conversion

Using a Safety First Thermometer simplifies the conversion process between Celsius and Fahrenheit. These thermometers are designed with user-friendly features, ensuring accurate and efficient temperature measurement. To convert, follow these steps:

- Ensure the thermometer is calibrated for precise readings.

- Take the temperature reading in the desired scale.

- If manual conversion is needed, use the formula: Fahrenheit = (Celsius × 9/5) + 32.

- For digital models, select the conversion option directly on the device.

Safety First Thermometers are built to provide reliable results, making them ideal for workplace safety and health applications. Their durability and ease of use ensure accurate conversions, minimizing errors and enhancing safety protocols. By utilizing these thermometers, professionals can maintain compliance with safety standards and ensure precise temperature measurements in any setting. This reliability is crucial for preventing hazards and maintaining a safe working environment.

Safety First Thermometer Instructions

Prepare the thermometer by calibrating it for accuracy. Operate it by following the manufacturer’s guidelines, ensuring proper placement for precise readings. Always prioritize safety and follow conversion instructions for Celsius to Fahrenheit measurements to maintain reliable results.

4.1 Preparing the Thermometer for Use

Before using a Safety First Thermometer, ensure it is properly prepared. Start by calibrating the device according to the manufacturer’s instructions to guarantee accuracy. Conduct a visual inspection to check for any damage or wear. If the thermometer is digital, insert fresh batteries or charge it as needed. For analog models, verify that the mercury or alcohol column is intact and free from obstructions. Ensure the thermometer is set to the correct temperature scale (Celsius or Fahrenheit) based on your requirements. Finally, review the user manual to familiarize yourself with specific operational guidelines. Proper preparation ensures reliable and precise temperature measurements, which are critical for safety and health applications.

4.2 Operating the Thermometer

Operating a Safety First Thermometer requires careful attention to ensure accurate and safe measurements. For digital thermometers, turn on the device and allow it to stabilize for a few seconds. Ensure the probe or sensor is clean and free from obstructions. When measuring temperature, insert the probe into the substance or hold it in the air, depending on the application. For analog models, gently shake down the mercury or alcohol column before use. Always follow the manufacturer’s guidelines for proper placement and waiting time to obtain precise readings. Avoid touching the sensor with bare hands to prevent heat transfer. Use the thermometer in well-ventilated areas, especially when measuring hazardous materials. Adhere to safety protocols to prevent accidents and ensure reliable results for workplace safety and health applications.

4.3 Reading and Interpreting Results

Reading and interpreting results from a Safety First Thermometer is straightforward but requires attention to detail. For digital thermometers, the display will show the temperature in either Celsius or Fahrenheit, depending on the model or settings. Analog thermometers will have a visible scale with markings indicating temperature levels. Always ensure the reading is stable and not fluctuating before recording. When interpreting, consider the context, such as safe temperature ranges for materials or environments. Be aware of safety thresholds to identify potential hazards. Double-check the unit of measurement to avoid confusion, especially when converting between Celsius and Fahrenheit. Accurate interpretation is crucial for maintaining workplace safety and health standards, as outlined in occupational safety guidelines. Proper documentation of readings ensures compliance with safety protocols and effective hazard prevention.

Safety Precautions When Using the Thermometer

Always handle thermometers with care to avoid breakage. Ensure proper calibration and follow manufacturer guidelines. Be aware of environmental factors that may affect accuracy.

5.1 Handling the Thermometer Safely

Handling a Safety First Thermometer requires attention to detail to ensure accuracy and safety. Always grasp the thermometer firmly but gently, avoiding excessive force that could cause damage. Use protective gloves if handling hazardous materials or in high-risk environments. Keep the thermometer away from direct sunlight or extreme temperatures, as this may affect its calibration. Avoid touching the sensing area with bare hands to prevent contamination. Store the thermometer in a protective case when not in use to prevent breakage. Regularly inspect the device for any signs of damage, such as cracks or worn-out seals. If the thermometer is damaged, do not use it until it has been properly repaired or replaced. Proper handling ensures reliable readings and extends the lifespan of the device.

5.2 Avoiding Common Hazards

Avoiding common hazards when using a Safety First Thermometer is essential for ensuring safe and accurate temperature measurement. Always handle the thermometer with care to prevent breakage, as shattered glass or damaged components can pose a risk; Avoid exposing the thermometer to extreme temperatures or chemicals, as this may compromise its accuracy or lead to malfunction. Never leave the thermometer unattended in hazardous environments, such as near open flames or electrical equipment. Use protective gloves when handling the device in high-risk settings to prevent accidental contamination or injury. Regularly inspect the thermometer for damage and ensure it is properly calibrated before use. By following these precautions, you can minimize risks and ensure reliable results in various applications.

5.3 Proper Storage and Maintenance

Proper storage and maintenance of a Safety First Thermometer are crucial for ensuring its accuracy and longevity. Store the thermometer in a protective case or pouch to prevent damage from drops or scratches. Avoid exposing it to extreme temperatures, moisture, or chemicals, as these can affect its performance. Regularly clean the thermometer with a soft cloth and mild soap solution to remove dirt or contaminants. For digital models, check the battery life and replace batteries as needed. Calibrate the thermometer periodically according to the manufacturer’s instructions to ensure precise readings. Proper maintenance not only extends the life of the device but also guarantees reliable results in critical safety and health applications. By following these guidelines, you can maintain the thermometer’s effectiveness and accuracy over time.

Maintenance and Troubleshooting

Regular maintenance and troubleshooting ensure Safety First Thermometers function accurately, crucial for workplace safety and reliable temperature measurement in both Celsius and Fahrenheit scales.

6.1 Calibrating the Thermometer

Calibrating a Safety First Thermometer ensures accurate temperature readings, essential for workplace safety and health. Start by immersing the thermometer in an ice water bath to verify the Celsius reading at 0°C. For Fahrenheit, ensure it reads 32°F. If adjustments are needed, use the calibration screw or digital controls. Regular calibration prevents measurement errors, which are critical in hazard prevention and control. Always follow the manufacturer’s instructions for precise adjustments. After calibration, test the thermometer with a known temperature source to confirm accuracy. Proper calibration ensures reliable readings, whether in Celsius or Fahrenheit, supporting safe and effective temperature measurement across various applications.

6.2 Cleaning and Sanitizing the Thermometer

Cleaning and sanitizing a Safety First Thermometer is essential for maintaining accuracy and preventing contamination. Use a soft, lint-free cloth dampened with mild soap and water to wipe the thermometer’s surface. Avoid harsh chemicals or abrasive materials that could damage the device. For digital thermometers, gently clean the probe and screen with a slightly damp cloth, ensuring no moisture seeps into the electronics. After cleaning, dry the thermometer thoroughly with a clean cloth to prevent water spots or residue. Regular cleaning ensures reliable temperature readings, whether in Celsius or Fahrenheit, and supports workplace safety and health standards. This practice is crucial for maintaining the thermometer’s performance and longevity.

Always follow the manufacturer’s cleaning instructions to avoid voiding the warranty or damaging the device. Proper sanitization helps prevent cross-contamination and ensures accurate measurements in various applications.

6.3 Troubleshooting Common Issues

Common issues with Safety First Thermometers may include inaccurate readings, display malfunctions, or conversion errors between Celsius and Fahrenheit. To address these, first ensure the thermometer is properly calibrated. Refer to the calibration instructions in the user manual. If the issue persists, check for battery life or damage from harsh chemicals. For digital thermometers, reset the device by turning it off and on again. Avoid exposing the thermometer to extreme temperatures or physical stress, as this can affect accuracy. Regular maintenance, such as cleaning and sanitizing, can prevent many issues. If problems remain unresolved, contact the manufacturer for support or replacement. Accurate temperature measurement is critical for workplace safety, so resolving issues promptly is essential.

Always follow the manufacturer’s troubleshooting guidelines to ensure the thermometer functions correctly and provides reliable readings in both temperature scales.

Frequently Asked Questions (FAQs)

- Why is accurate temperature measurement crucial for safety?

- How do I convert Celsius to Fahrenheit using a Safety First Thermometer?

- What calibration steps ensure precise readings?

These questions address common concerns about thermometer accuracy, conversion, and maintenance, ensuring safe and reliable temperature monitoring in various settings.

7.1 Why is Temperature Measurement Important for Safety?

Temperature measurement is critical for ensuring safety in various environments. Accurate readings help prevent hazards, such as overheating equipment or unsafe environmental conditions. In workplaces, precise temperature monitoring protects workers from heat-related illnesses and ensures compliance with safety standards. Thermometers play a vital role in maintaining safe conditions, whether in industrial settings, healthcare, or everyday use. They enable early detection of potential risks, allowing for timely interventions to prevent accidents. For instance, measuring extreme temperatures can alert individuals to dangers like freezing conditions or fire hazards. Reliable temperature data is essential for safeguarding health, preventing equipment damage, and upholding overall safety protocols. Without accurate measurements, risks escalate, leading to potential harm to people and property.

7.2 How to Choose the Right Thermometer for Your Needs

Selecting the right thermometer involves considering accuracy, durability, and ease of use. Ensure the device meets your specific requirements, such as temperature range and measurement scale (Celsius or Fahrenheit). For industrial settings, opt for rugged designs that withstand harsh conditions. In healthcare, prioritize thermometers with quick response times and hygienic features. Consider whether you need specialized types, like infrared or digital thermometers, for specific tasks. Always check for certifications and compliance with safety standards. User-friendly interfaces and clear displays enhance safety and efficiency. Assess additional features, such as memory storage or alarms, based on your needs. By evaluating these factors, you can choose a thermometer that ensures accurate and reliable temperature measurement, supporting safety and effectiveness in various applications.

7.3 What is the Difference Between Contact and Infrared Thermometers?

Contact thermometers require physical contact with the object to measure temperature, ensuring high accuracy for precise readings. They are ideal for industrial and laboratory settings where stability and reliability are crucial. Infrared thermometers, however, measure temperature remotely using thermal radiation, offering non-invasive and rapid readings. They are perfect for hazardous environments, moving objects, or situations where contact could damage the surface. Both types are essential for workplace safety, but their applications vary. Contact thermometers are cost-effective and durable, while infrared models provide convenience and speed. Understanding their differences helps in selecting the right tool for specific tasks, ensuring accurate and safe temperature measurement in various industries.

Safety First Thermometers are essential for accurate temperature measurement, ensuring workplace safety and health by providing reliable readings in both Celsius and Fahrenheit, crucial for maintaining safe conditions.

8.1 Summary of Key Points

Accurate temperature measurement is vital for workplace safety and health, with thermometers playing a crucial role in hazard prevention and control. Understanding Celsius and Fahrenheit scales ensures reliable readings, essential for maintaining safe conditions. Proper handling and conversion between scales, using formulas or Safety First Thermometers, enhance precision. Regular calibration and maintenance of thermometers are necessary for accuracy. Employers and workers must adhere to safety protocols, including proper storage and handling, to prevent accidents. For further assistance, resources like the Occupational Safety and Health Administration (OSHA) provide guidance. By following these practices, workplaces can minimize risks and ensure a safe environment. Temperature measurement is a foundational aspect of safety, directly impacting health and operational efficiency across industries.

8.2 Final Tips for Safe and Accurate Temperature Measurement

For safe and precise temperature measurement, always use a calibrated thermometer and follow the manufacturer’s instructions. Ensure proper handling to avoid damage or inaccuracies. When converting between Celsius and Fahrenheit, use reliable formulas or tools to maintain accuracy. Regularly clean and sanitize thermometers to prevent contamination. Store them in a protective case to avoid breakage. For workplace safety, ensure all employees are trained in proper thermometer use and hazard prevention; Refer to resources like OSHA guidelines for additional safety protocols. By adhering to these practices, you can ensure reliable temperature measurements, contributing to a safer and healthier environment. Accurate readings are essential for preventing risks and maintaining operational efficiency in any setting.